Our fully-integrated, efficient and flexible supply chain meets the needs of our growers, buyers and end use customers.

Careful storage and handling, close to the point of origination, allows us to maintain the quality of the grain we receive from growers and ensure it is available when consumers need it.

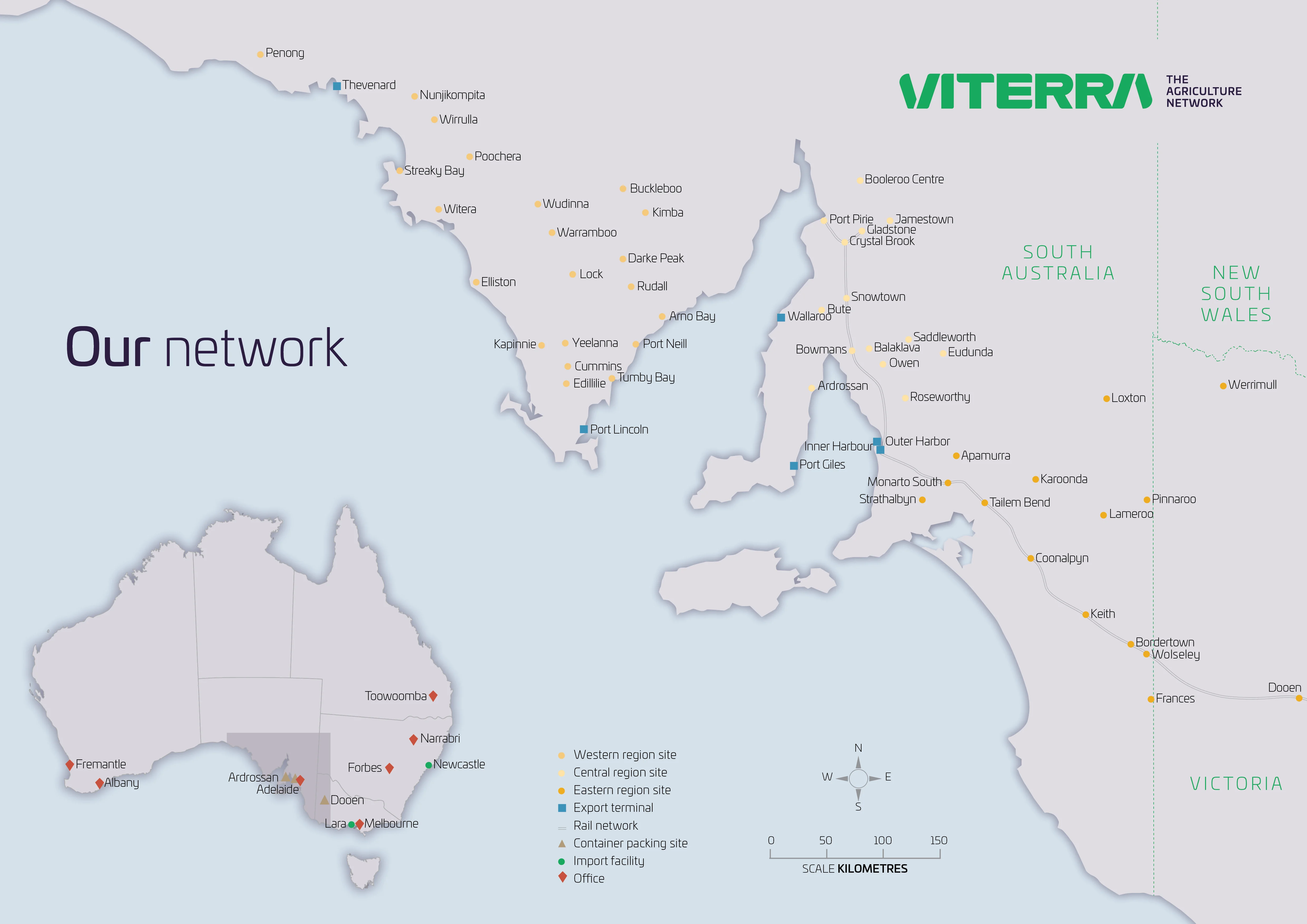

Our logistics network provides customers with rail and road transport services to move commodities efficiently through our network.

We have six bulk grain export port terminals strategically located along the coastline of South Australia. These port terminals can efficiently load various size vessels.

Viterra’s packing and processing facilities provide a large range of containerised export options from locations around southern and eastern Australia.

Quality management and food safety are integrated into all of our activities and operations.

Domestic services

Viterra provides domestic outturn services to growers, grain buyers and end users who have delivered or purchased grain in the Viterra network.

Viterra facilitates this service by managing stock availability on a regional basis throughout the whole year. At times outturn sites may vary from where the stock was delivered or bought.

Viterra’s processes in managing this service uniquely allows stock to be accessed throughout harvest and during heavy export shipping periods.

Domestic outturn conditions for growers are set out in the receival service and warehousing terms and conditions and can be arranged by contacting their local regional office.

Domestic outturn conditions for grain buyers are set out in Schedule E of the pricing, procedures and protocols manual and can be arranged by e-mailing

Domestic_Outturns@viterra.com

Packing and processing

Viterra operates one of Australia’s largest container packing and processing facilities, with sites based in south and eastern Australia.

We offer a large range of packaging options to suit our customer’s specific requirements.

Our services include:

- Bulk container packing

- Grower receival

- Machine cleaning

- Fumigation (Methyl Bromide option available)

- Blending

- Bagged container packing (Dooen only)

Established over 25 years ago, our experienced packing and processing team can help clients achieve their specific export requirements.

For general packing and processing enquiries, call (03) 9864 2088 or email shipping.vpp@viterra.com.

All of our sites have:

- Department of Agriculture registration, with multiple approved officers on each site

- ISO 22000 certification, ensuring food production quality assurance

- Grainsoft IT system, built specifically for the packing business

- Soft handling equipment for handling pulses

- Contracted supply chain operators, assuring wharf delivery service 24/7

- Container parks on site enabling early pick up and management of container logistics

Contacts

General packing and processing enquiries

Phone: (03) 9864 2088

Email: shipping.vpp@viterra.com

|

Contact Mark Abell, Operations Coordinator Lot 5571/LOT 50 Silo Rd |

- Located on the Yorke Peninsula

- 5,000 container capacity (freight contractor – rapid haulage, road)

- 450,000 tonne of storage capacity including bunkers

- Mobile container packer that allows for live loading

- Portable cleaning options

|

Contact Trevor May, Operations Coordinator |

- Located in Port Adelaide – part of Inner Harbour terminal

- 10,000 container capacity (freight contractor – rapid haulage, road)

- Inverter packing facility connected to Block 1 of terminal, ensuring multiple storage options

- Portable cleaning options

Contact Adam Carter, Site Manager |

- Located in Wimmera, western Victoria

- 9000 container capacity per annum (freight contractor – SCT, road/rail)

- Segregated silo storage

- 200,000 tonne bunker storage

- Equipped with a mobile container packer that allows maximised barley tonnage (23 tonne malting)

- Full cleaning available, including two cimbria cleaners and a gravity table

|

Contact Mark Abell, Operations Coordinator Lot 5571/LOT 50 Silo Rd |

- Located on the Yorke Peninsula

- 5,000 container capacity (freight contractor – rapid haulage, road)

- 450,000 tonne of storage capacity including bunkers

- Mobile container packer that allows for live loading

- Portable cleaning options

|

Contact Trevor May, Operations Coordinator |

- Located in Port Adelaide – part of Inner Harbour terminal

- 10,000 container capacity (freight contractor – rapid haulage, road)

- Inverter packing facility connected to Block 1 of terminal, ensuring multiple storage options

- Portable cleaning options

Contact Adam Carter, Site Manager |

- Located in Wimmera, western Victoria

- 9000 container capacity per annum (freight contractor – SCT, road/rail)

- Segregated silo storage

- 200,000 tonne bunker storage

- Equipped with a mobile container packer that allows maximised barley tonnage (23 tonne malting)

- Full cleaning available, including two cimbria cleaners and a gravity table

Port terminals

The port of Thevenard is 793 kilometres west of Adelaide and 3 kilometres from the centre of Ceduna.

Facility information

| Ship loader type |

1 travelling gantry with retractable boom and spout attached No trimming heads available Spout trimming only |

| Number of belts | 1 |

| Number of spouts | 1 |

| Air draft | 14m |

| Indicative loading rate | 1000 tonnes/hour |

Berth details and restrictions

Port Lincoln is situated at the southern tip of Eyre Peninsula, 682 km from Adelaide by road and 280km west by air. A natural deep water harbour makes Port Lincoln attractive to large bulk grain carriers for topping up loads from shallow ports in South Australia and Victoria.

Facility information

| Ship loader type |

2 travelling gantry loaders Spout trimming only |

| Number of belts | 2 |

| Number of spouts | 2 |

| Air draft | 22.3m |

| Indicative loading rate | 3000 tonnes/hour |

Berth details and restrictions

The port of Wallaroo is situated on the eastern side of Spencer Gulf, 160km by road and 197 nautical miles from Adelaide.

Facility information

| Ship loader type |

5 identical slewing loading booms with spouts attached (operate 2 at a time) Spout trimming only |

| Number of belts | 1 |

| Number of spouts | 5 |

| Air draft | 12.9m |

| Indicative loading rate | 800 tonnes/hour |

Berth details and restrictions

Port Giles features a deep-water berth, situated on the eastern side of Yorke Peninsula, 217km by road and 35 nautical miles from Adelaide.

Facility Information

| Ship loader type |

5 identical slewing loading booms with spouts attached No trimming heads available Spout trimming only |

| Number of belts | 1 |

| Number of spouts | 5 |

| Air draft | 15.5m |

| Indicative loading rate | 1000 tonnes/hour |

Berth details and restrictions

Situated near the mouth of the Port River, Outer Harbor is 11km downstream of the Inner Harbour grain berth. Outer Harbor was custom-built on the deep-water berth to allow larger vessels to load.

Facility information

| Ship loader type |

Cleveland cascade chute travelling loader Trimming head attached to loader when hold trimming |

| Number of belts | 1 |

| Number of spouts | 1 |

| Air draft | 24.4m |

| Indicative loading rate | 2200 tonnes/hour |

Berth Details and Restrictions

Inner Harbour grain berth is situated on the Port River, 11km upstream of Outer Harbor.

Facility information

| Ship loader type |

1 travelling gantry loader Spout trimming only |

| Number of belts | 1 |

| Number of spouts | 1 |

| Air draft | 14.7m |

| Indicative loading rate | 800 tonnes/hour |

Berth details and restrictions

Navigational restrictions may apply to some larger vessels. See Inner Harbour’s berth details and restrictions.